Los Tipos de Coleccionistas Más Comunes

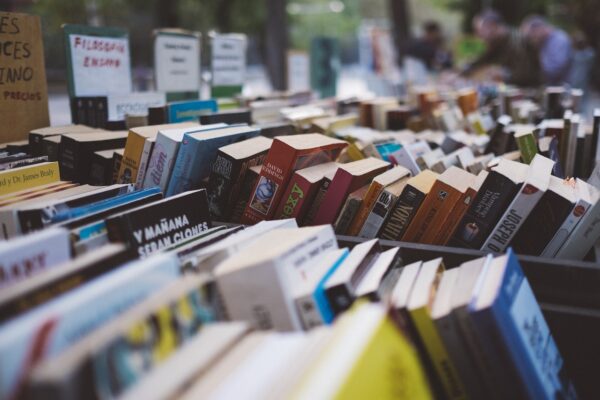

El mundo del coleccionismo es vasto y diverso, con personas apasionadas por adquirir y preservar[…]

Leer másNoticias de Ciencia, Tecnología, Salud, Economía. Diario Digital

El mundo del coleccionismo es vasto y diverso, con personas apasionadas por adquirir y preservar[…]

Leer más

La astrología es una parte de la ciencia que tiene miles de años de existir,[…]

Leer más

En Hotmail iniciar sesión en bandeja de entrada tiene amplia variedad de funciones, en este[…]

Leer más

El mundo del cine ha visto una gran cantidad de éxitos a lo largo de[…]

Leer más